PRESSURE SEAL TILTING CHECK VALVES

PRESSURE SEAL TILTING CHECK VALVES

To go directly to a specific product class, click on the icons below.

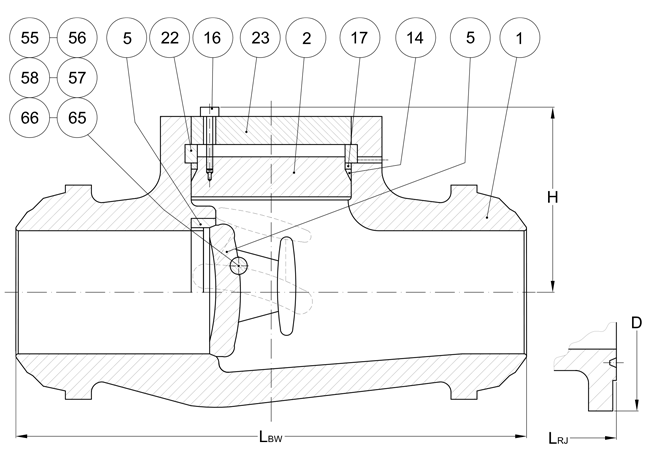

CLASS 600 – Fig. 3262SB

CHARACTERISTICS

- Pressure Seal, Tilting type disc

- Welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat |

| 5 | Disc |

| 14 | Gasket |

| 16 | Stud bolt |

| 17 | Spacer ring |

| 22 | Segmented retainer ring |

| 23 | Bonnet retainer |

| 55 | Disc pin |

| 56 | Plug of flange |

| 57 | Gasket for ditto |

| 58 | Spacer washer |

| 65 | Blind flange stud |

| 66 | Nut for ditto |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 600 TABLE

| NB | 2½" | 3" | 4" | 6" | 8" | 10" |

|---|---|---|---|---|---|---|

| L BW | 216 | 254 | 305 | 457 | 584 | 711 |

| L RF | 330 | 356 | 432 | 559 | 660 | 787 |

| L RJ | 333 | 359 | 435 | 562 | 664 | 791 |

| D | 190.5 | 209.5 | 273 | 355.5 | 419 | 508 |

| H | 200 | 200 | 200 | 200 | 290 | 350 |

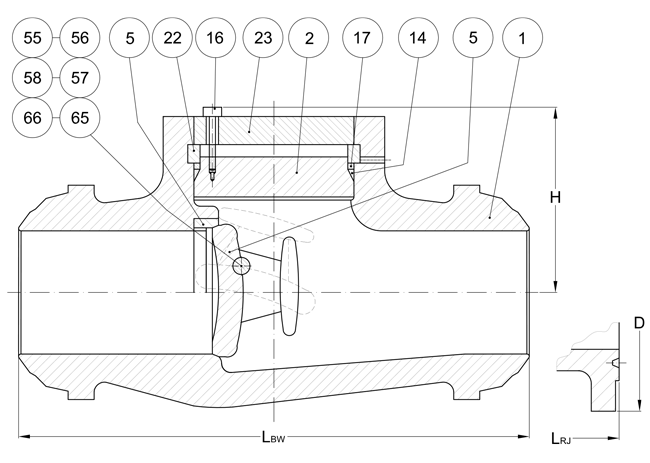

CLASS 900 – Fig. 3267SB

CHARACTERISTICS

- Pressure Seal, Tilting type disc

- Welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat |

| 5 | Disc |

| 14 | Gasket |

| 16 | Stud bolt |

| 17 | Spacer ring |

| 22 | Segmented retainer ring |

| 23 | Bonnet retainer |

| 55 | Disc pin |

| 56 | Plug of flange |

| 57 | Gasket for ditto |

| 58 | Spacer washer |

| 65 | Blind flange stud |

| 66 | Nut for ditto |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 900 TABLE

| NB | 4" | 6" | 8" | 10" | 12" | 14" |

|---|---|---|---|---|---|---|

| L BW - L RF | 457 | 610 | 737 | 838 | 965 | 1029 |

| L RJ | 460 | 613 | 740 | 841 | 968 | 1038 |

| D | 292 | 381 | 470 | 546 | 609.5 | 641.5 |

| H | 120 | 185 | 241 | 305 | 343 | 370 |

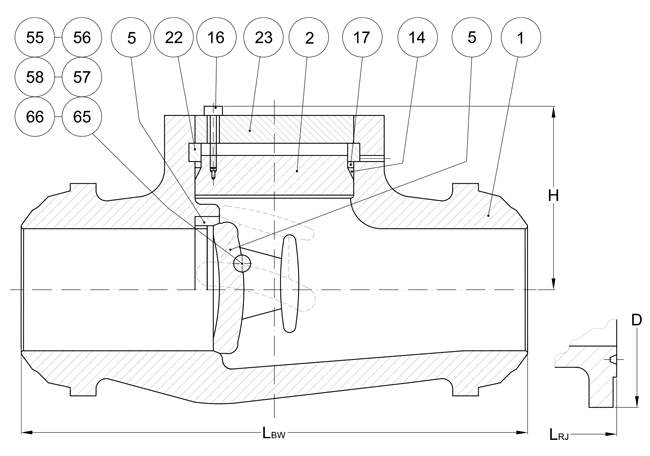

CLASS 1500 – Fig. 3272SB

CHARACTERISTICS

- Pressure Seal, Tilting type disc

- Welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat |

| 5 | Disc |

| 14 | Gasket |

| 16 | Stud bolt |

| 17 | Spacer ring |

| 22 | Segmented retainer ring |

| 23 | Bonnet retainer |

| 55 | Disc pin |

| 56 | Plug of flange |

| 57 | Gasket for ditto |

| 58 | Spacer washer |

| 65 | Blind flange stud |

| 66 | Nut for ditto |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

VDR TILTING PRESSURE SEAL 1500 TABLE

| NB | 3" | 4" | 6" | 8" | 10" |

|---|---|---|---|---|---|

| L BW - L RF | 470 | 546 | 705 | 832 | 991 |

| L RJ | 473 | 549 | 711 | 841 | 1000 |

| D | 266.5 | 311 | 393.5 | 482.5 | 584 |

| H | 110 | 135 | 192 | 250 | 311 |

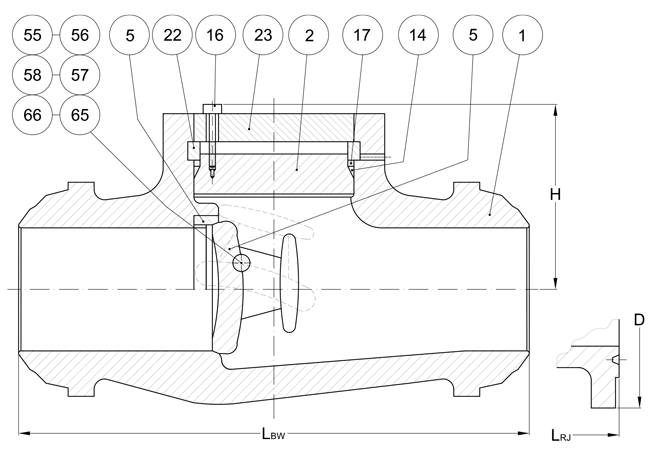

CLASS 2500 – Fig. 3277SB

CHARACTERISTICS

- Pressure Seal, Tilting type disc

- Welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat |

| 5 | Disc |

| 14 | Gasket |

| 16 | Stud bolt |

| 17 | Spacer ring |

| 22 | Segmented retainer ring |

| 23 | Bonnet retainer |

| 55 | Disc pin |

| 56 | Plug of flange |

| 57 | Gasket for ditto |

| 58 | Spacer washer |

| 65 | Blind flange stud |

| 66 | Nut for ditto |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 2500 TABLE

| NB | 2½" | 3" | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|---|

| L BW - L RF | 508 | 578 | 673 | 914 | 1022 | 1270 | 1422 |

| L RJ | 514 | 584 | 683 | 927 | 1038 | 1292 | 1445 |

| D | 266.5 | 305 | 355.5 | 482.5 | 552.5 | 673 | 762 |

| H | 110 | 130 | 160 | 230 | 295 | 370 | 410 |