CRYOGENIC GLOBE VALVES

CRYOGENIC GLOBE VALVES

To go directly to a specific product class, click on the icons below.

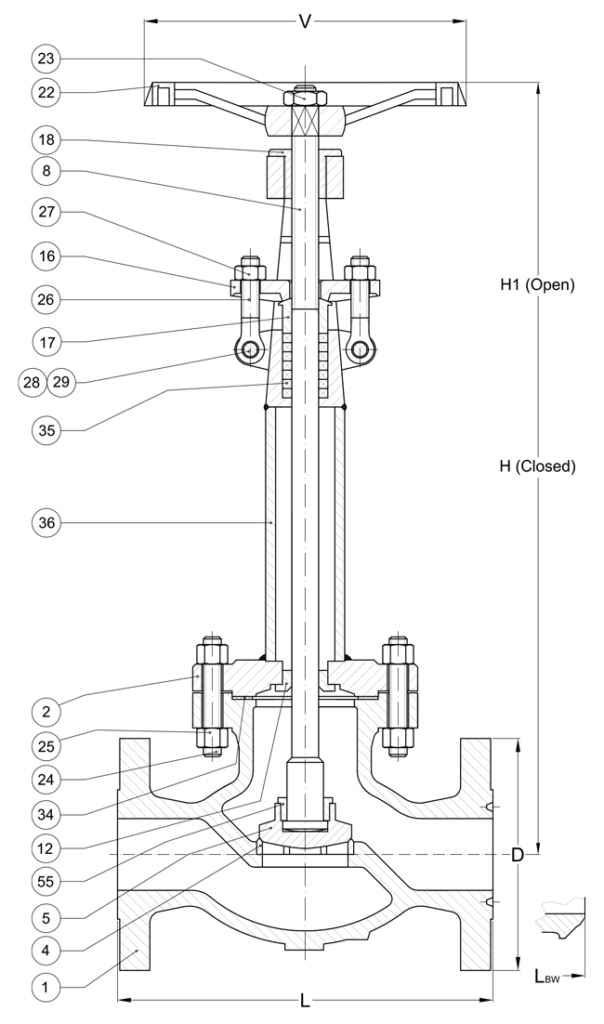

CLASS 150 – Fig. 1090EB

CHARACTERISTICS

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

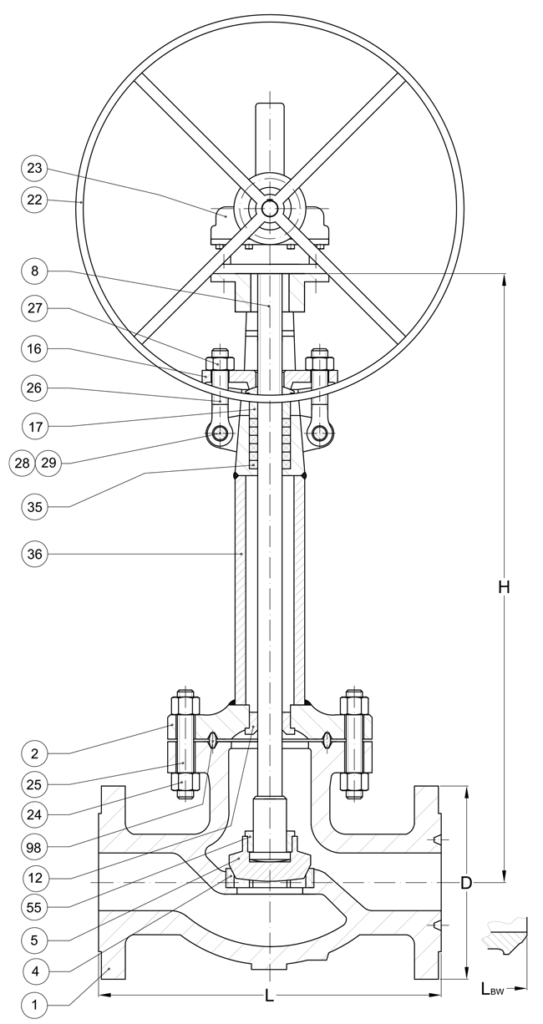

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 5 | Disc |

| 8 | Stem |

| 12 | Bonnet bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 34 | Bonnet Gasket |

| 35 | Packing |

| 36 | Tube Extension |

| 55 | Disc Nut |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, BS 1873, API 6D

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 150 TABLE

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" |

|---|---|---|---|---|---|---|---|---|---|---|---|

| L - L BW | 203 | 241 | 292 | 406 | 495 | 622 | 699 | 787 | 914 | 978 | 978 |

| D | 152 | 191 | 229 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 698 |

| E | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 500 | 500 |

| H | 585 | 680 | 705 | 830 | 1015 | 1100 | 1185 | 1335 | 1335 | 1460 | 1460 |

| H1 | 605 | 740 | 740 | 880 | 1080 | 1185 | 1340 | 1420 | 1420 | 1625 | 1625 |

| V | 200 | 250 | 250 | 300 | 425 | 500 | 500 | 600 | 600 | 800 | 800 |

| H | 285 | 380 | 405 | 530 | 615 | 700 | 785 | 935 | 935 | 960 | 960 |

| H1 | 305 | 440 | 440 | 580 | 680 | 785 | 940 | 1020 | 1020 | 1125 | 1125 |

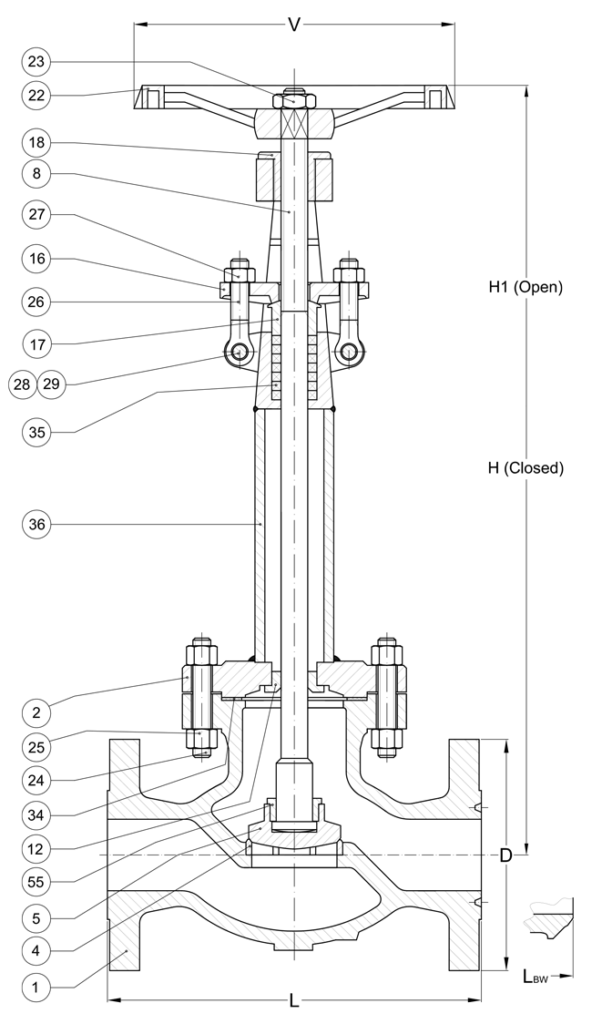

CLASS 300 – Fig. 1092EB

CHARACTERISTICS

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 5 | Disc |

| 8 | Stem |

| 12 | Bonnet bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 34 | Bonnet Gasket |

| 35 | Packing |

| 36 | Tube Extension |

| 55 | Disc Nut |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, BS 1873, API 6D

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 300 TABLE

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 20" |

|---|---|---|---|---|---|---|---|---|---|

| L - L BW | 267 | 318 | 356 | 445 | 559 | 622 | 711 | 762 | 1016 |

| L RJ | 283 | 333 | 371 | 460 | 575 | 638 | 727 | 778 | 1035 |

| D | 165 | 210 | 254 | 318 | 381 | 444 | 521 | 584 | 775 |

| E | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 500 |

| H | 595 | 665 | 710 | 915 | 1105 | 1220 | 1250 | 1310 | 1710 |

| H1 | 615 | 705 | 750 | 965 | 1170 | 1300 | 1350 | 1410 | 1850 |

| V | 200 | 250 | 250 | 425 | 500 | 500 | 600 | 600 | 800 |

| H | 295 | 365 | 410 | 615 | 705 | 820 | 850 | 910 | 1210 |

| H1 | 315 | 405 | 450 | 665 | 770 | 900 | 950 | 1010 | 1350 |

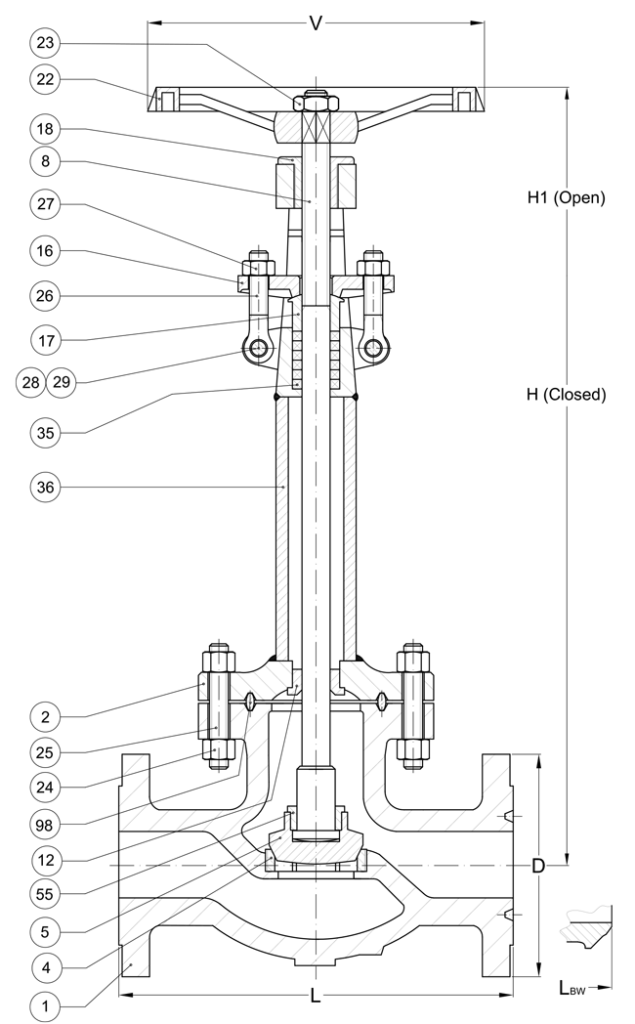

CLASS 600 – Fig. 1094EB

CHARACTERISTICS

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 5 | Disc |

| 8 | Stem |

| 12 | Bonnet bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 36 | Tube Extension |

| 55 | Disc Nut |

| 98 | Bonnet Gasket |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, BS 1873, API 6D

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 600 TABLE

| NB | 2" | 2 ½" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" |

|---|---|---|---|---|---|---|---|---|---|---|

| L RF -L BW | 292 | 330 | 356 | 432 | 559 | 660 | 787 | 838 | 889 | 991 |

| L RJ | 295 | 333 | 359 | 435 | 562 | 664 | 791 | 841 | 892 | 994 |

| E | 300 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 |

| D | 165 | 165 | 210 | 273 | 356 | 419 | 508 | 559 | 603 | 686 |

| H | 730 | 735 | 785 | 860 | 1050 | 1300 | 1435 | 1570 | 1750 | 1750 |

| H1 | 750 | 760 | 815 | 895 | 1108 | 1375 | 1525 | 1660 | 1880 | 1880 |

| V | 225 | 225 | 300 | 350 | 500 | 600 | 800 | 800 | 900 | 1000 |

| H | 430 | 435 | 485 | 560 | 750 | 900 | 1035 | 1170 | 1350 | 1350 |

| H1 | 450 | 460 | 515 | 595 | 808 | 975 | 1125 | 1260 | 1480 | 1480 |

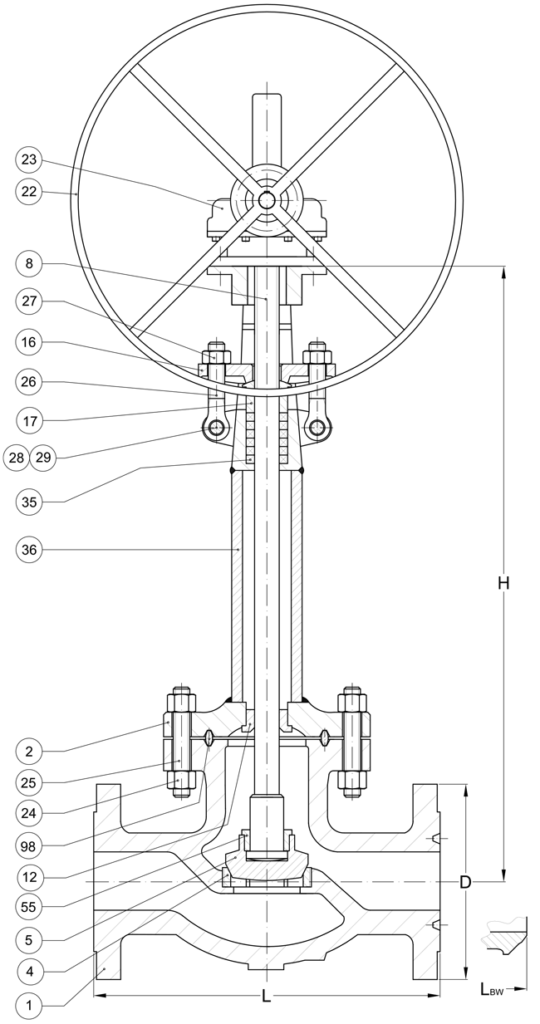

CLASS 900 – Fig. 1096EB

CHARACTERISTICS

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 5 | Disc |

| 8 | Stem |

| 12 | Bonnet bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 36 | Tube Extension |

| 55 | Disc Nut |

| 98 | Bonnet Gasket |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, BS 1873, API 6D

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 900 TABLE

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|---|

| L RF -L BW | see 1500# table | 381 | 457 | 610 | 737 | 838 | 965 |

| L RJ | see 1500# table | 384 | 460 | 613 | 740 | 841 | 968 |

| D | see 1500# table | 241 | 292 | 381 | 470 | 546 | 610 |

| E | see 1500# table | 300 | 300 | 300 | 400 | 400 | 400 |

| H | see 1500# table | 760 | 920 | 960 | 1195 | 1300 | 1675 |

| V | see 1500# table | 350 | 425 | 500 | 600 | 800 | 1000 |

| H | see 1500# table | 460 | 620 | 660 | 795 | 900 | 1275 |

CLASS 1500 – Fig. 1098EB

CHARACTERISTICS

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

TABLE PICTURE DETAILS

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 5 | Disc |

| 8 | Stem |

| 12 | Bonnet bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 36 | Tube Extension |

| 55 | Disc Nut |

| 98 | Bonnet Gasket |

PART DETAILS

According to following standards:

- Design and Manufacture: ANSI B16.34, BS 1873, API 6D

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 1500 TABLE

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|---|

| L RF -L BW | 368 | 470 | 546 | 705 | 832 | 991 | 1130 |

| L RJ | 371 | 473 | 549 | 711 | 841 | 1000 | 1146 |

| D | 216 | 267 | 311 | 394 | 483 | 584 | 673 |

| E | 300 | 300 | 300 | 300 | 400 | 400 | 400 |

| H | 780 | 910 | 1025 | 1330 | 1600 | 1790 | 1940 |

| V | 300 | 500 | 600 | 800 | 800 | 800 | 1000 |

| H | 480 | 610 | 725 | 1030 | 1200 | 1390 | 1540 |