SARACINESCHE BOLTED BONNET

SARACINESCHE BOLTED BONNET

Per andare direttamente a una classe di prodotto specifica, fai clic sulle icone di seguito.

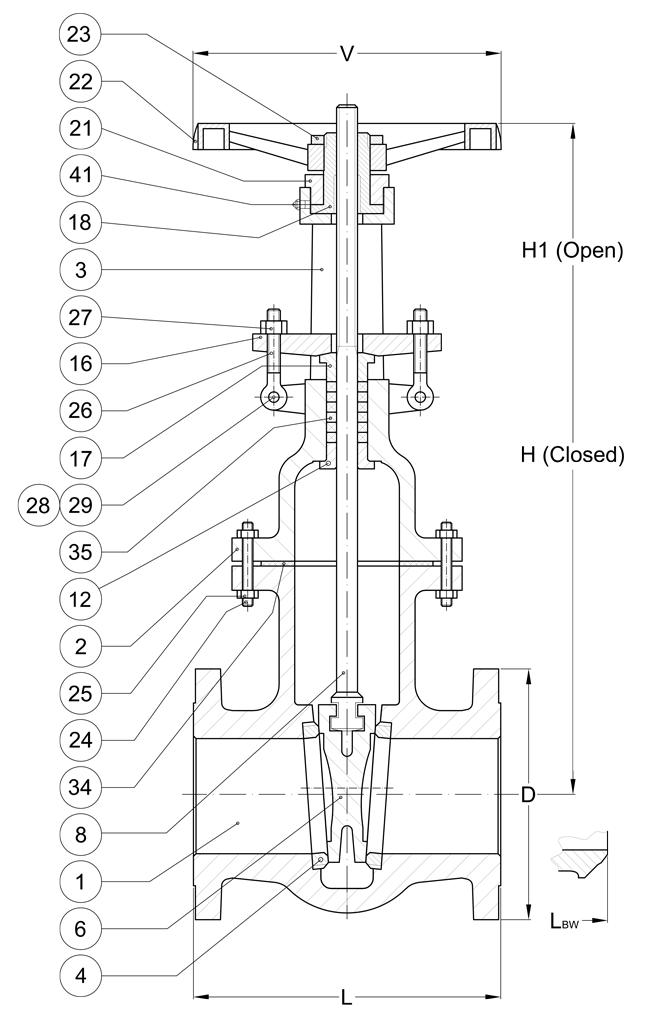

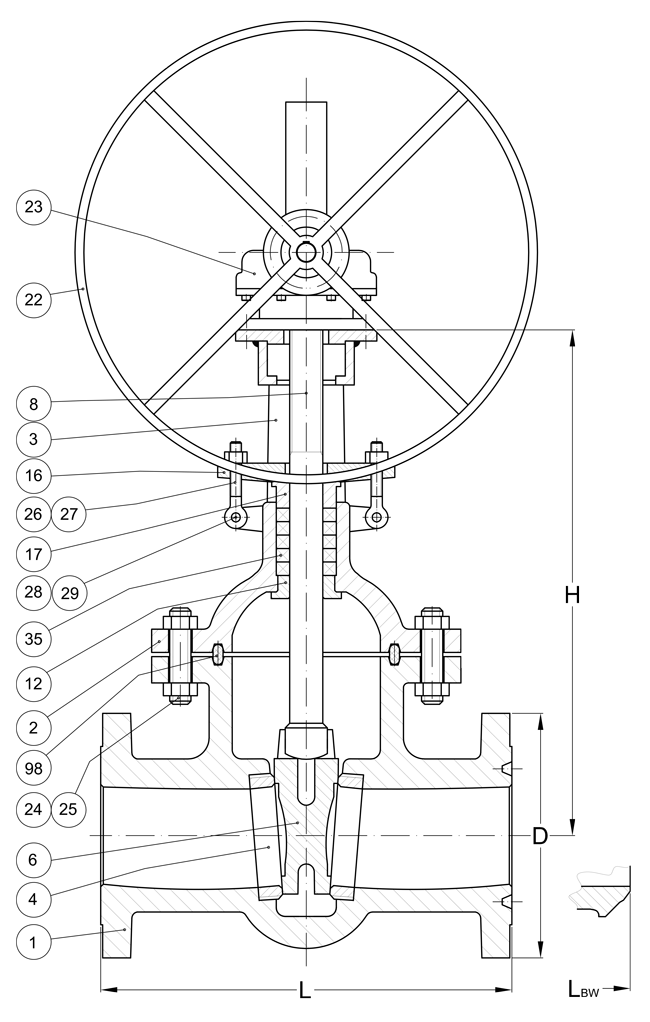

CLASSE 150 – Fig. 2120

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 21 | Yam Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 34 | Bonnet Gasket |

| 35 | Packing |

| 41 | Grease Fitting |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D, ISO 5208

CLASSE 150 TABELLA

| NB | 2" | 2½" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 22" | 24" | 28" | 30" | 32" | 34" | 36" | 40" | 48" | 54" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L-RF | 178 | 191 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 | 508 | 610 | 610 | 660 | 711 | 711 | 762 | 864 | 1067 |

| L-BW | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 571 | 610 | 660 | 711 | 711 | 813 | 914 | 914 | 965 | 1016 | 1016 | 1168 | 1270 | 1422 |

| D | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 698 | 749 | 813 | 927 | 984 | 1060 | 1111 | 1168 | 1289 | 1511 | 1683 |

| H | 295 | 305 | 365 | 445 | 460 | 610 | 740 | 910 | 1075 | 1220 | 1305 | 1475 | 1630 | 1895 | 1935 | 2270 | 2625 | 2690 | 2925 | 2920 | 3200 | 3700 | 4440 |

| H1 | 350 | 370 | 445 | 555 | 585 | 770 | 950 | 1165 | 1395 | 1505 | 1705 | 1920 | 2140 | 2485 | 2540 | 2980 | 3400 | 3465 | 3790 | 3845 | 4260 | 4900 | 5800 |

| V | 200 | 200 | 200 | 250 | 250 | 300 | 350 | 425 | 500 | 500 | 600 | 600 | 600 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 | 1600 |

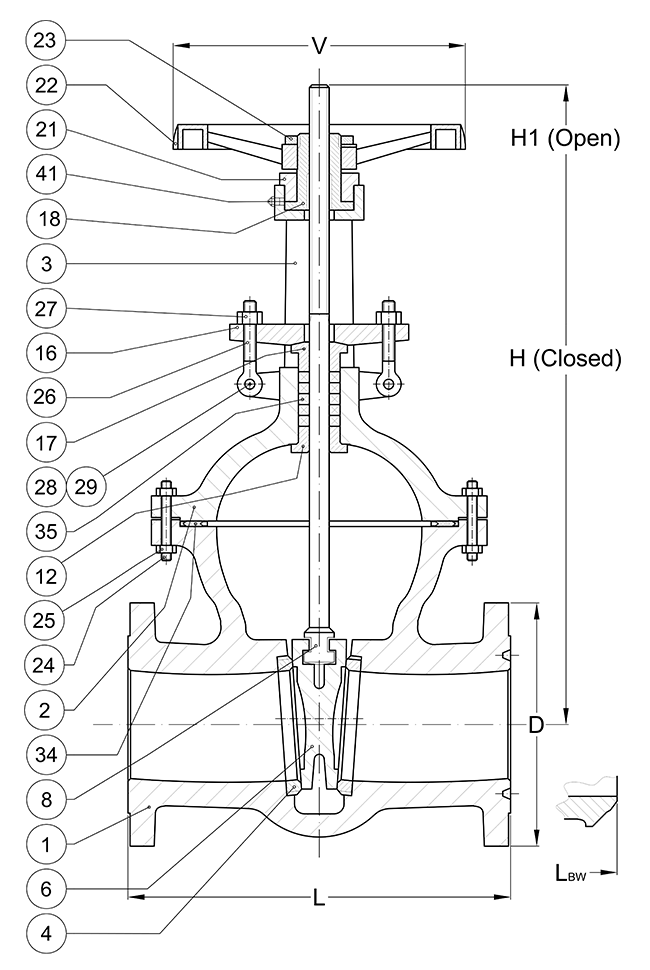

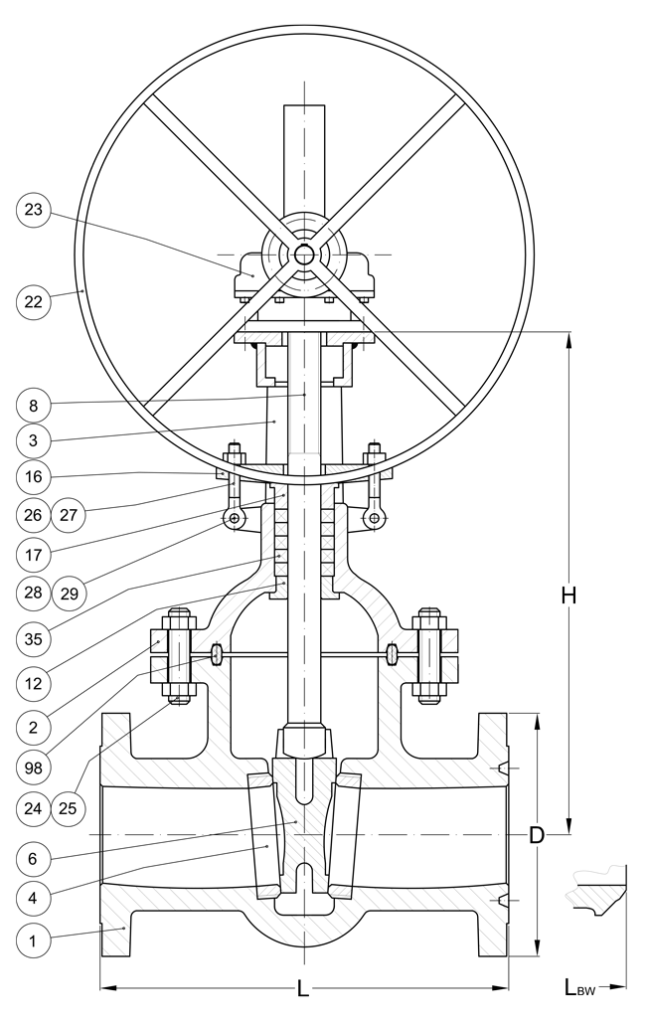

CLASSE 300 – Fig. 2130

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 21 | Yam Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 34 | Bonnet Gasket |

| 35 | Packing |

| 41 | Grease Fitting |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 300 TABELLA

| NB | 2" | 2½" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" | 28" | 30" | 32" | 36" | 48" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 | 1346 | 1397 | 1397 | 1727 | 1727 |

| L RJ | 232 | 257 | 298 | 321 | 397 | 419 | 435 | 473 | 518 | 778 | 854 | 930 | 1010 | 1165 | 1372 | 1422 | 1426 | 1756 | - |

| D | 165 | 190 | 210 | 254 | 280 | 318 | 381 | 444 | 521 | 584 | 648 | 771 | 775 | 914 | 1035 | 1092 | 1149 | 1270 | 1465 |

| H | 320 | 325 | 445 | 485 | 490 | 675 | 825 | 970 | 1125 | 1260 | 1550 | 1575 | 1735 | 2065 | 2500 | 2590 | 2900 | 3200 | 3325 |

| H1 | 375 | 395 | 530 | 595 | 615 | 945 | 1035 | 1220 | 1435 | 1605 | 1970 | 2035 | 2240 | 2675 | 3200 | 3360 | 3800 | 4200 | 4525 |

| V | 200 | 200 | 225 | 250 | 250 | 350 | 425 | 500 | 500 | 500 | 600 | 800 | 800 | 1000 | 1000 | 1600 | 1000 | 1000 | 2000 |

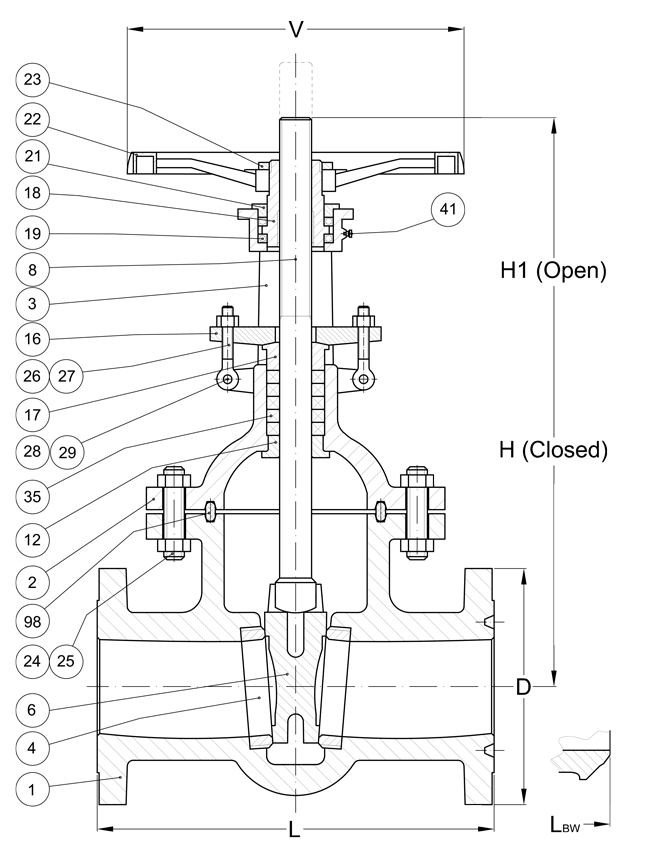

CLASSE 600 – Fig. 2140

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 21 | Yam Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 41 | Grease Fitting |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 600 TABELLA

| NB | 2" | 2½" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" | 30" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | 292 | 330 | 356 | 432 | 432 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 | 1651 |

| L RJ | 295 | 333 | 359 | 435 | 435 | 562 | 664 | 790 | 841 | 892 | 994 | 1095 | 1200 | 1406 | 1664 |

| D | 165 | 191 | 210 | 273 | 330 | 356 | 419 | 508 | 559 | 603 | 686 | 743 | 813 | 940 | 1130 |

| H | 400 | 400 | 470 | 620 | 625 | 750 | 1060 | 1040 | 1375 | 1355 | 1675 | 1800 | 2135 | 2260 | 3600 |

| H1 | 455 | 455 | 550 | 715 | 735 | 915 | 1280 | 1305 | 1685 | 1510 | 2070 | 2250 | 2615 | 2880 | 4350 |

| V | 225 | 225 | 250 | 350 | 350 | 500 | 600 | 600 | 600 | 800 | 800 | 1000 | 1000 | 1000 | 1000 |

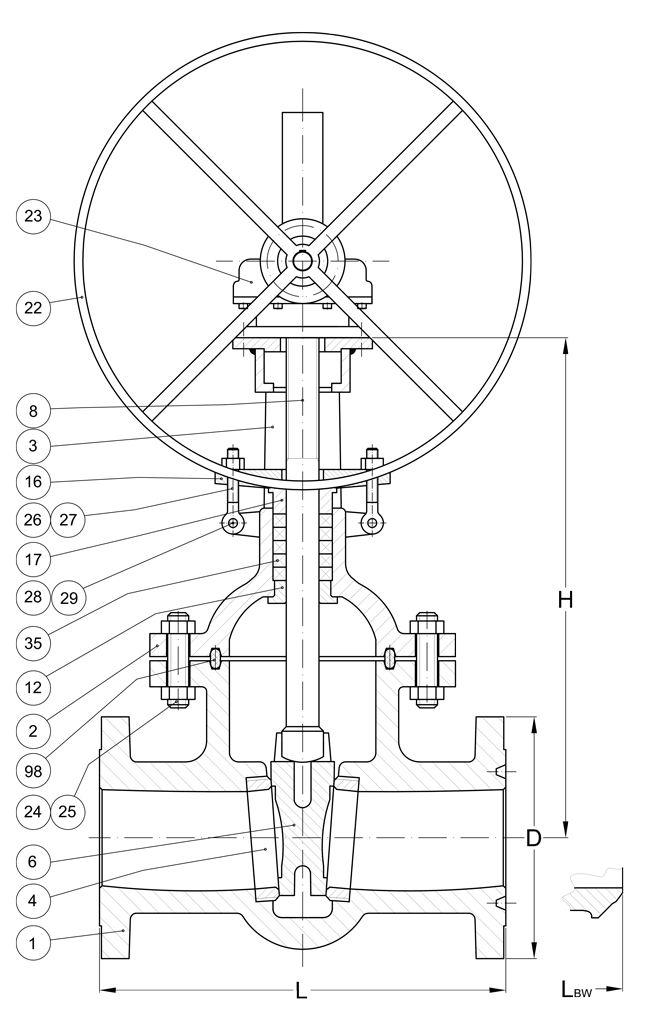

CLASSE 900 – Fig. 2150

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 3 | Yoke |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 900 TABELLA

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" |

|---|---|---|---|---|---|---|---|---|

| L RF - L BW | see 1500# table | 381 | 457 | 610 | 737 | 838 | 965 | 1029 |

| L RJ | see 1500# table | 384 | 460 | 613 | 740 | 841 | 968 | 1038 |

| D | see 1500# table | 241 | 292 | 381 | 470 | 546 | 610 | 642 |

| H | see 1500# table | 585 | 710 | 730 | 1050 | 1230 | 1305 | 1275 |

CLASSE 1500 – Fig. 2160

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 3 | Yoke |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 1500 TABELLA

| NB | 2" | 2½" | 3" | 4" | 6" | 8" | 10" | 12" | 14" |

|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | 368 | 419 | 470 | 546 | 705 | 832 | 991 | 1130 | 1257 |

| L RJ | 371 | 422 | 473 | 549 | 711 | 841 | 1000 | 1146 | 1276 |

| D | 216 | 245 | 267 | 311 | 394 | 483 | 584 | 673 | 749 |

| H | 375 | 590 | 635 | 745 | 975 | 1135 | 1400 | 1415 | 1560 |

CLASSE 2500 – Fig. 2170

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 3 | Yoke |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 2500 TABELLA

| NB | 2" | 2½" | 3" | 4" | 6" | 8" |

|---|---|---|---|---|---|---|

| L RF - L BW | 451 | 508 | 578 | 673 | 914 | 1022 |

| L RJ | 454 | 514 | 584 | 683 | 927 | 1038 |

| D | 235 | 267 | 305 | 356 | 483 | 552 |

| H | 600 | 620 | 680 | 870 | 1065 | 1235 |