VALVOLE DI RITEGNO A PISTONE

VALVOLE DI RITEGNO A PISTONE

Le caratteristiche costruttive di questo modello raccomandano il loro uso con i liquidi. Possono essere a pieno flusso, a flusso libero o ad angolo. Possono avere una molla per accelerare la chiusura.

Per andare direttamente a una classe di prodotto specifica, fai clic sulle icone di seguito.

CLASSE 600

CARATTERISTICHE

- Bolted Cover, Piston type Closure

- Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

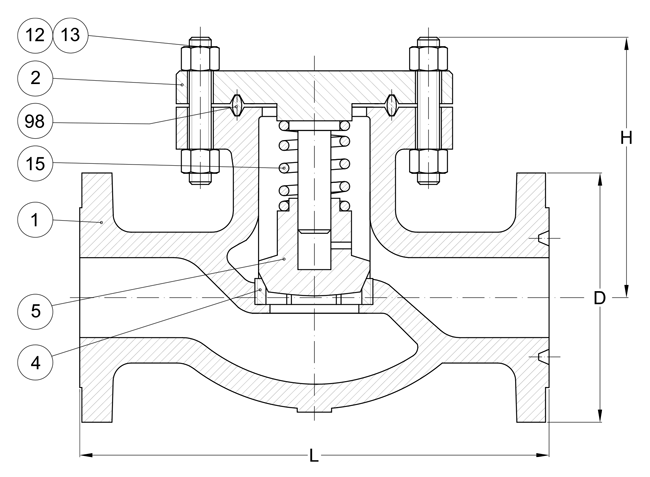

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Cover |

| 4 | Seat Ring |

| 5 | Piston |

| 12 | Bonnet Stud |

| 13 | Nut |

| 98 | Ring joint |

| 15 | Spring |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 600 TABELLA

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|---|

| L RF - L BW | 292 | 356 | 432 | 559 | 660 | 787 | 838 |

| L RJ | 295 | 359 | 435 | 562 | 664 | 791 | 841 |

| D | 165 | 210 | 273 | 356 | 419 | 508 | 559 |

| H | 175 | 220 | 270 | 360 | 400 | 500 | 530 |

CLASSE 900

CARATTERISTICHE

- Bolted Cover, Piston type Closure

- Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

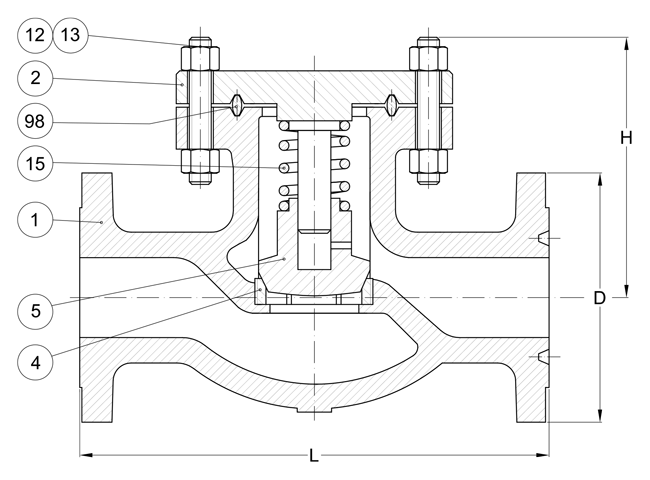

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Cover |

| 4 | Seat Ring |

| 5 | Piston |

| 12 | Bonnet Stud |

| 13 | Nut |

| 98 | Ring joint |

| 15 | Spring |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASS 900 TABELLA

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | see 1.500# table | 381 | 457 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | 1549 |

| L RJ | 384 | 460 | 613 | 740 | 841 | 968 | 1038 | 1140 | 1232 | 1334 | 1568 | |

| D | 241 | 292 | 381 | 470 | 546 | 610 | 641 | 705 | 788 | 857 | 1041 | |

| H | 265 | 300 | 380 | 455 | 535 | 630 | 670 | 750 | 850 | 900 | 1000 |

CLASSE 1500

CARATTERISTICHE

- Bolted Cover, Piston type Closure

- Threaded or welded seat ring

- Body and Cover materials: ASTM A216 WCB,A217 WC1, A217 WC6, A217 WC9,A217 C5, A217 C12, A217 C12A, A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), AluBronze (CC333G, BS1400 AB2, B148 C95800), Nickel Alloys(Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

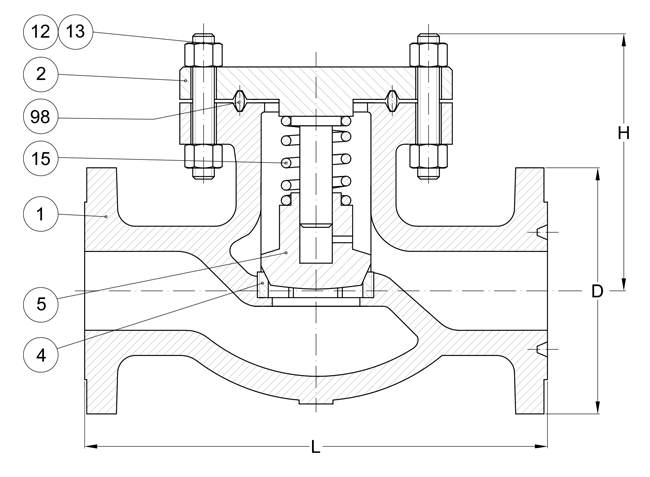

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Cover |

| 4 | Seat Ring |

| 5 | Piston |

| 12 | Bonnet Stud |

| 13 | Nut |

| 98 | Ring joint |

| 15 | Spring |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 6D, BS1868

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 1500 TABELLA

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|---|

| L RF - L BW | 368 | 470 | 546 | 705 | 832 | 991 | 1130 |

| L RJ | 371 | 473 | 549 | 711 | 841 | 1000 | 1146 |

| D | 216 | 267 | 311 | 394 | 483 | 584 | 673 |

| H | 245 | 315 | 375 | 455 | 565 | 650 | 750 |