SARACINESCHE PER SERVIZIO CRIOGENICO

SARACINESCHE PER SERVIZIO CRIOGENICO

Per andare direttamente a una classe di prodotto specifica, fai clic sulle icone di seguito.

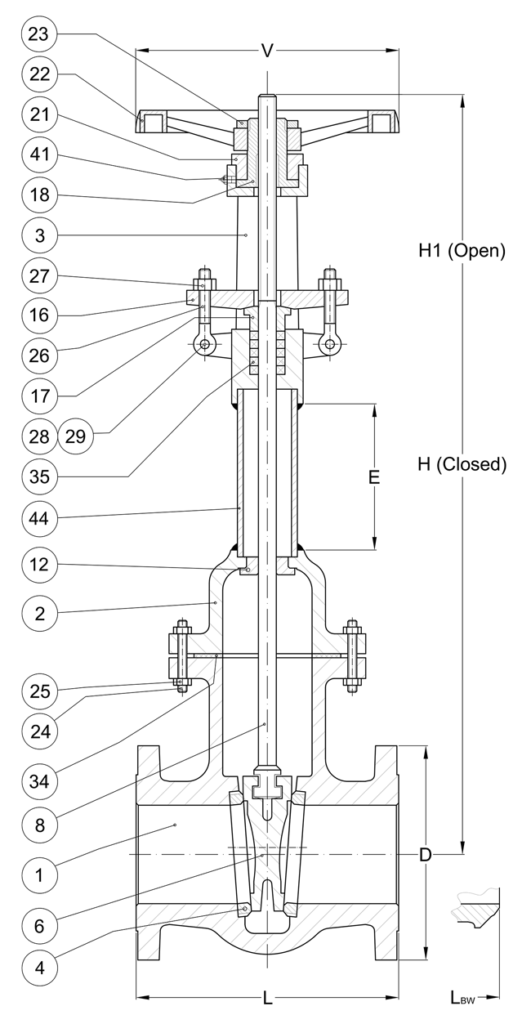

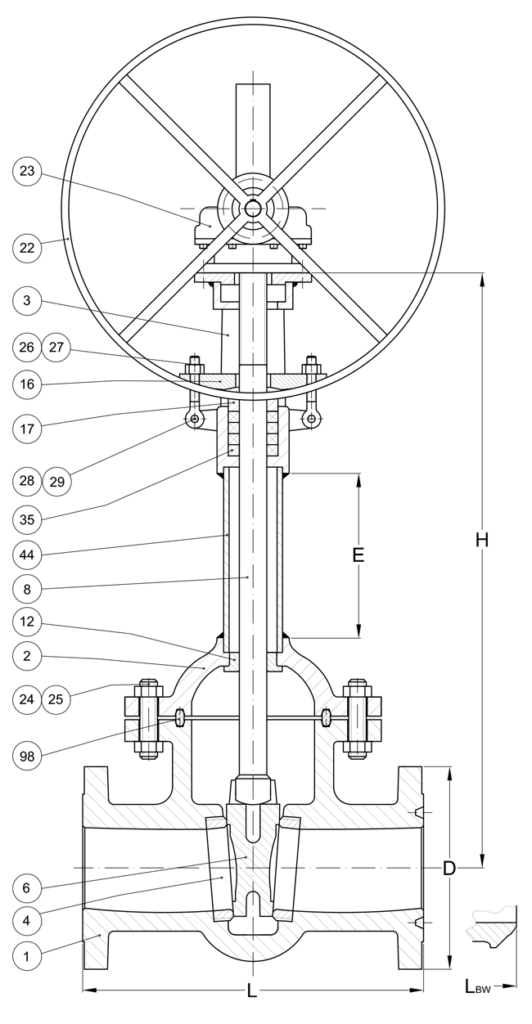

CLASSE 150 – Fig. 2120EB

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 21 | Yam Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 34 | Bonnet Gasket |

| 35 | Packing |

| 41 | Grease Fitting |

| 44 | Tube Extension |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 150 TABELLA

| NB | 2" | 2½" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 22" | 24" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L RF | 178 | 191 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 | 508 |

| L BW | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 571 | 610 | 660 | 711 | 711 | 813 |

| D | 152 | 178 | 191 | 229 | 254 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 698 | 749 | 813 |

| E | 300 | 300 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 500 | 500 | 500 | 500 |

| H | 595 | 605 | 665 | 745 | 760 | 910 | 1140 | 1310 | 1475 | 1620 | 1705 | 1975 | 2130 | 2395 | 2435 |

| H1 | 650 | 670 | 745 | 855 | 885 | 1070 | 1350 | 1565 | 1795 | 1905 | 2105 | 2420 | 2640 | 2985 | 3040 |

| V | 200 | 200 | 200 | 250 | 250 | 300 | 350 | 425 | 500 | 500 | 600 | 600 | 600 | 800 | 800 |

| H | 295 | 305 | 365 | 445 | 460 | 610 | 740 | 910 | 1075 | 1220 | 1305 | 1475 | 1630 | 1895 | 1935 |

| H1 | 350 | 370 | 445 | 555 | 585 | 770 | 950 | 1165 | 1395 | 1505 | 1705 | 1920 | 2140 | 2485 | 2540 |

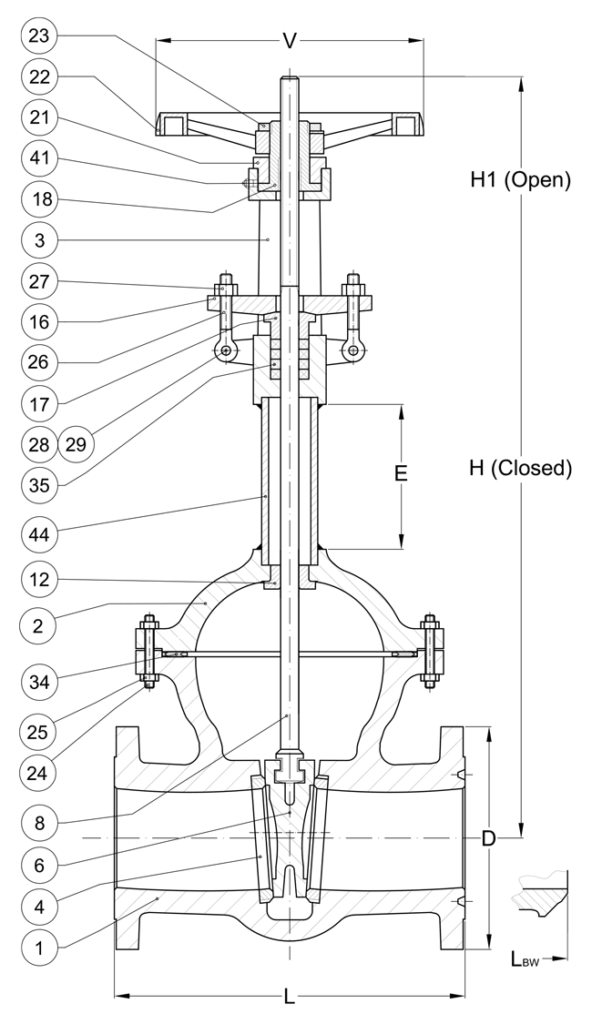

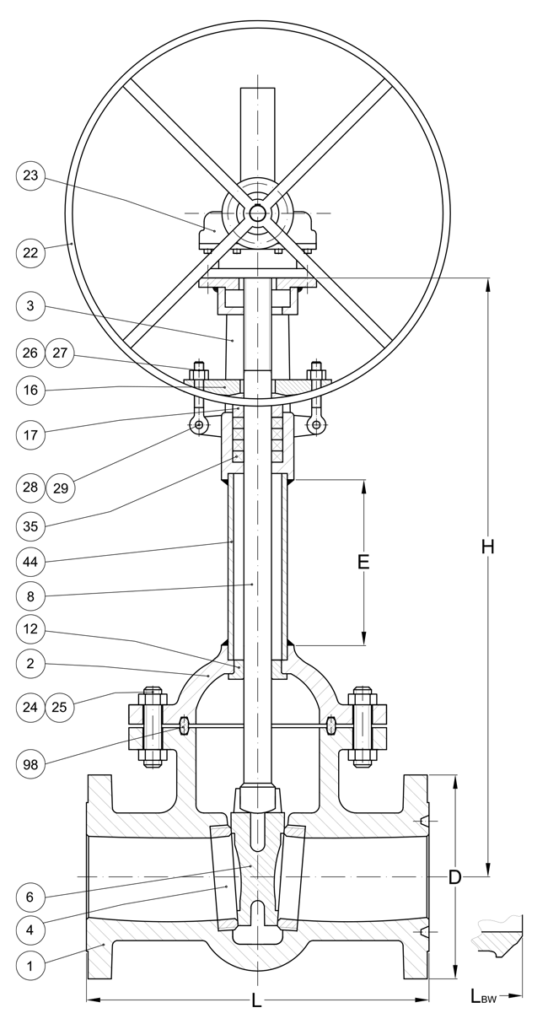

CLASSE 300 – Fig. 2130EB

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 21 | Yam Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 34 | Bonnet Gasket |

| 35 | Packing |

| 41 | Grease Fitting |

| 44 | Tube Extension |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 300 TABELLE

| NB | 2" | 2½" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | 216 | 241 | 283 | 305 | 381 | 403 | 419 | 457 | 502 | 762 | 838 | 914 | 991 | 1143 |

| L RJ | 232 | 257 | 298 | 321 | 397 | 419 | 435 | 473 | 518 | 778 | 854 | 930 | 1010 | 1165 |

| D | 165 | 190 | 210 | 254 | 280 | 318 | 381 | 444 | 521 | 584 | 648 | 771 | 775 | 914 |

| E | 300 | 300 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 500 | 500 | 500 |

| H | 620 | 625 | 745 | 785 | 790 | 975 | 1225 | 1370 | 1525 | 1660 | 1950 | 2075 | 2235 | 2565 |

| H1 | 675 | 695 | 830 | 895 | 915 | 1245 | 1435 | 1620 | 1835 | 2005 | 2370 | 2535 | 2740 | 3175 |

| V | 200 | 200 | 225 | 250 | 250 | 350 | 425 | 500 | 500 | 500 | 600 | 800 | 800 | 1000 |

| H | 320 | 325 | 445 | 485 | 490 | 675 | 825 | 970 | 1125 | 1260 | 1550 | 1575 | 1735 | 2065 |

| H1 | 375 | 395 | 530 | 595 | 615 | 945 | 1035 | 1220 | 1435 | 1605 | 1970 | 2035 | 2240 | 2675 |

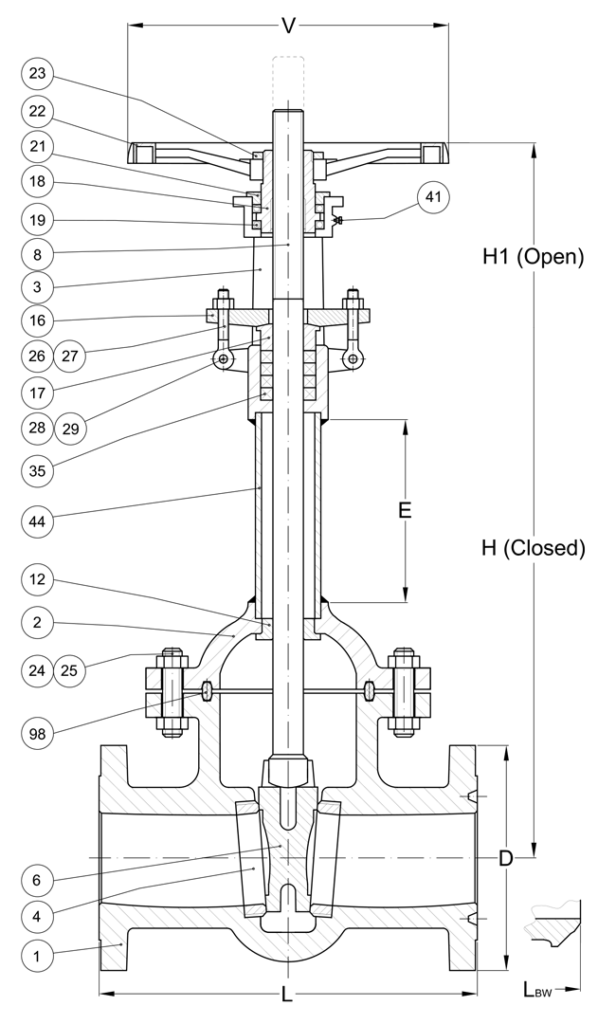

CLASSE 600 – Fig. 2140EB

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 18 | Yoke Nut |

| 21 | Yam Nut |

| 22 | Handwheel |

| 23 | Wheel Nut |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 41 | Grease Fitting |

| 44 | Tube Extension |

| 45 | Connection Flange |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 600 TABELLA

| NB | 2" | 2½" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | 292 | 330 | 356 | 432 | 432 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 |

| L RJ | 295 | 333 | 359 | 435 | 435 | 562 | 664 | 790 | 841 | 892 | 994 | 1095 | 1200 | 1406 |

| D | 165 | 191 | 210 | 273 | 330 | 356 | 419 | 508 | 559 | 603 | 686 | 743 | 813 | 940 |

| E | 300 | 300 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | 400 | 500 | 500 | 500 |

| H | 700 | 700 | 770 | 920 | 925 | 1050 | 1460 | 1440 | 1775 | 1755 | 2075 | 2300 | 2635 | 2760 |

| H1 | 755 | 755 | 850 | 1015 | 1035 | 1215 | 1680 | 1705 | 2085 | 1910 | 2470 | 2750 | 3115 | 3380 |

| V | 225 | 225 | 250 | 350 | 350 | 500 | 600 | 600 | 600 | 800 | 800 | 1000 | 1000 | 1000 |

| H | 400 | 400 | 470 | 620 | 625 | 750 | 1060 | 1040 | 1375 | 1355 | 1675 | 1800 | 2135 | 2260 |

| H1 | 455 | 455 | 550 | 715 | 735 | 915 | 1280 | 1305 | 1685 | 1510 | 2070 | 2250 | 2615 | 2880 |

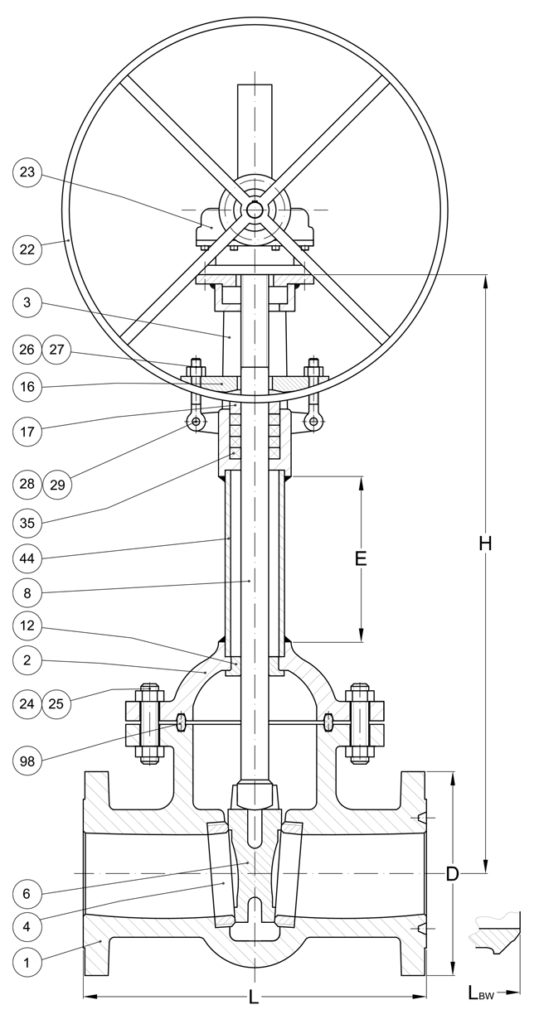

CLASSE 900 – Fig. 2150EB

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 44 | Tube Extension |

| 45 | Connection Flange |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 900 TABELLA

| NB | 2" | 3" | 4" | 6" | 8" | 10" | 12" | 14" |

|---|---|---|---|---|---|---|---|---|

| L RF - L BW | see 1.500# table | 381 | 457 | 610 | 737 | 838 | 965 | 1029 |

| L RJ | see 1.500# table | 384 | 460 | 613 | 740 | 841 | 968 | 1038 |

| D | see 1.500# table | 241 | 292 | 381 | 470 | 546 | 610 | 642 |

| E | see 1.500# table | 300 | 300 | 300 | 400 | 400 | 400 | 400 |

| H | see 1.500# table | 885 | 1010 | 1220 | 1450 | 1630 | 1705 | 1675 |

| H | see 1.500# table | 585 | 710 | 920 | 1050 | 1230 | 1305 | 1275 |

CLASSE 1500 – Fig. 2160EB

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 44 | Tube Extension |

| 45 | Connection Flange |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 1500 TABELLA

| NB | 2" | 2½" | 3" | 4" | 6" | 8" | 10" | 12" | 14" |

|---|---|---|---|---|---|---|---|---|---|

| L RF - L BW | 368 | 419 | 470 | 546 | 705 | 832 | 991 | 1130 | 1257 |

| L RJ | 371 | 422 | 473 | 549 | 711 | 841 | 1000 | 1146 | 1276 |

| D | 216 | 245 | 267 | 311 | 394 | 483 | 584 | 673 | 749 |

| E | 300 | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 |

| H | 675 | 890 | 935 | 1045 | 1275 | 1535 | 1800 | 1815 | 1960 |

| H | 375 | 590 | 635 | 745 | 975 | 1135 | 1400 | 1415 | 1560 |

CLASSE 2500 – Fig. 2150EB

CARATTERISTICHE

- OS&Y, Rising stem, Flexible Wedge, Extended Bonnet

- Bolted Bonnet, Threaded or welded seat ring

- Body and Cover materials: A352 LCB, A352 LCC, A351 CF8, A351 CF8M, A351 CF8C, A351 CF3, A351 CF3M, A351 CN7M, Duplex and Superduplex (A890/995 Gr.4A, A890/A995 Gr.5A, A890/A995 Gr.6A), Nickel Alloys( Inconel® 625, Incoloy® 825, Hastelloy® C276), Monel® and according to customer request.

DETTAGLI DELL’IMMAGINE

| No | Part Name |

|---|---|

| 1 | Body |

| 2 | Bonnet |

| 4 | Seat Ring |

| 6 | Wedge |

| 8 | Stem |

| 12 | Bonnet Bushing |

| 16 | Gland Flange |

| 17 | Gland |

| 22 | Handwheel |

| 23 | Gear Operator |

| 24 | Bonnet Stud |

| 25 | Nut |

| 26 | Eye Bolt |

| 27 | Nut |

| 28 | Eye Bolt Pin |

| 29 | Nut |

| 35 | Packing |

| 44 | Tube Extension |

| 45 | Connection Flange |

| 98 | Bonnet Gasket |

DETTAGLI DEL MODELLO

According to following standards:

- Design and Manufacture: ANSI B16.34, API 600 API 6D, API 603, BS1414

- Face to face (end to end): ANSI B16.10, API6D

- Flanged connection: 2″~24″ to ANSI B16.5, 26″~36″ to MSS-SP-44 or to API 605, to ANSI B16.47 on request

- Butt welded end: ANSI B16.25

- Test and inspection: API 598, API 6D

CLASSE 2500 TABELLA

| NB | 2" | 2½" | 3" | 4" | 6" | 8" |

|---|---|---|---|---|---|---|

| L RF - L BW | 451 | 508 | 578 | 673 | 914 | 1022 |

| L RJ | 454 | 514 | 584 | 683 | 927 | 1038 |

| D | 235 | 267 | 305 | 356 | 483 | 552 |

| H | 835 | 887 | 985 | 1226 | 1548 | 1787 |

| H | 600 | 620 | 680 | 870 | 1065 | 1235 |